Applications, Installation, and Cost Factors

At easycraft, our three applications of panels are Moisture Resistant Medium Density Fiberboard (MR) MDF for General Purpose, Ultra-High Moisture Resistant (UHMR) MDF for Wet Area Interior, and Compressed Hardwood for our Semi Exterior.

All are versatile options that offer distinct qualities and applications. In this blog, we'll dive into the differences between these materials, their various uses, installation methods, and the cost factors associated with each.

Understanding the Materials

Medium Density Fiberboard (MDF)

MDF stands for Medium-Density Fibreboard. It is a type of engineered wood product that is made from wood fibres that are compressed and bonded together with resins. MDF is a smooth and uniform board surface with no splitting, splinters, or knot holes and can be easily cut, drilled, painted, and veneered. The density of MDF ranges from 650 to 850 kg/m3, making it impact resistant and 300% tougher than traditional plasterboards. Our Moisture Resistant MDF is recognizable by the easyJOIN green tongue, and the substrate is a straw colour.

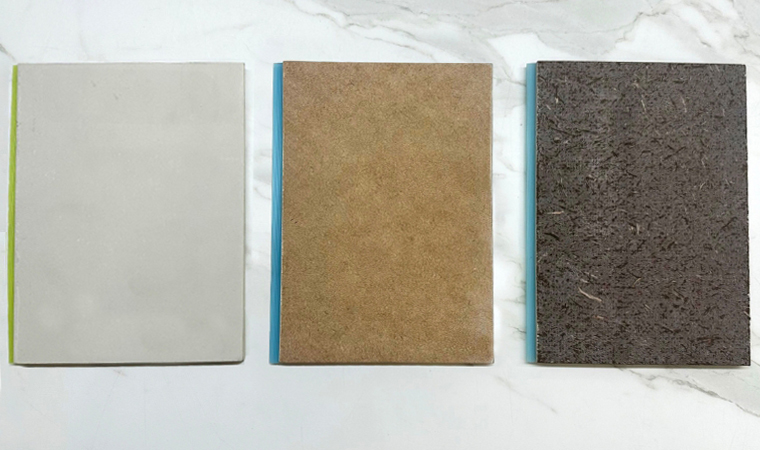

Above: General Purpose (MR) MDF panels identified by the green tongue and lighter colour internal substrate.

Ultra-High Moisture Resistant MDF

Ultra-High Moisture Resistant MDF (UHMR) is a special type of MDF that has the same principles as General Purpose MDF, however, has a higher resistance to moisture and humidity than standard MDF. This makes it perfect for Wet Area Interior applications. (UHMR) MDF is made with a water-resistant resin and emulsified wax that reduces the swelling and warping of the board when exposed to humid conditions. This application is recognised by the easyJOIN blue tongue and is also a lighter straw colour.

Above: Wet Area Interior (UHMR) MDF panels identified by the blue tongue and lighter internal substrate.

Compressed Hardwood

Compressed Hardwood, also known as high-density compressed wood, is also a type of engineered wood product that is made of hardwood that has been compressed under high pressure and heat. Compressed hardwood is more durable and stable than softwood and can be recognised by the blue tongue easyJOIN system and is chocolate brown in substrate colouring.

Above: Easycraft Semi Exterior (Compressed Hardwood) panels identified by the blue tongue and dark brown internal substrate.

The Applications

Moisture Resistant (MR) MDF: easycraft General Purpose

(MR) MDF finds application in a wide range of projects. Its smooth surface and uniform consistency make it ideal for General Purpose applications such as furniture, cabinetry, decorative wall and ceiling panels, and moldings. Its ability to be cut, routed, and shaped precisely without splintering makes it a favorite among craftsmen and carpenters. However, it should be noted that (MR) MDF is not suitable for areas with high moisture levels.

Ultra-High Moisture Resistant (UHMR) MDF: easycraft Wet Area Interior

Thanks to its enhanced moisture resistance, this type of MDF is perfect for Wet Area Interior spaces with high humidity, such as bathrooms, kitchens, and laundry rooms. It can be used around bathroom vanities, kitchen cabinets, and shelving units where exposure to high humidity is more likely. Its ability to resist swelling or warping due to moisture makes it a reliable choice in such environments.

Compressed Hardwood: easycraft Semi Exterior

Compressed Hardwood's exceptional strength and durability make it suitable for applications that demand structural integrity such as Semi Exterior applications. Its resistance to wear and tear makes it an excellent option for long-lasting, heavy-use projects. Our easycraft Semi Exterior panels are perfect for exterior undercover area walls and ceiling linings. Residential applications such as alfresco, patio, outdoor rooms, BBQ areas and commercial applications such as toilet blocks, outdoor kitchens, laundries, garages, and storage units.

The Installation

Moisture Resistant MDF: easycraft General Purpose

Installing our easycraft General Purpose MRMDF panels is relatively straightforward. They can be cut, drilled, and shaped using standard woodworking tools. For (MR) MDF, it's essential to take precautions against moisture by sealing the edges and surfaces with appropriate primers and paints. The average 9mm x 1200mm x 2400mm board weighs 20kg so you may need a hand getting into place.

Ultra-High Moisture Resistant MDF: easycraft Wet Area Interior

(UHMR) MDF, though more resistant to moisture, should still be installed with care in areas where it might encounter water. The average 9mm x 1200mm x 2400mm board also weighs 20kg so you may need a hand getting into place. You can find more information on our technical data and wet area installation guides.

Compressed Hardwood: Easycraft Semi Exterior

Due to its density, compressed hardwood may require specialised tools for cutting and shaping. Pre-drilling holes for screws and fasteners is recommended to prevent splitting. Compressed hardwood should also be sealed or finished to protect it from environmental factors and enhance its appearance. The average sheet 9.5mm x 1200mm x 2745mm weighs 32kg so assistance with sheets will be needed.

The Cost Factors

Moisture Resistant MDF: easycraft General Purpose

MDF is known for its affordability. It's often more budget-friendly compared to solid wood or other engineered wood products, making it an attractive option for projects with cost constraints.

Ultra-High Moisture Resistant MDF: easycraft Wet Area Interior

This type of MDF typically comes at a slightly higher cost than standard MDF due to its specialised moisture-resistant properties. The added cost is justified by its suitability for damp environments.

Compressed Hardwood: easycraft Semi Exterior

Compressed hardwood is generally more expensive than MDF due to its enhanced strength and durability. Investment in compressed hardwood is often worth it for projects that require a sturdy, long-lasting material.

Above: The reverse side of our General Purpose (MR) MDF, Wet Area Interior (UHMR) MDF and Semi Exterior (Compressed Hardwood) panels.

Each of the three substrates found in easycraft panels offers distinct advantages based on their composition, applications, installation requirements, and cost considerations. Moisture Resistant MDF is versatile and cost-effective, while Ultra-High Moisture Resistant MDF adds resilience against dampness. Compressed hardwood is prized for its exceptional strength. When selecting the right material for a project, understanding these differences is key to achieving the desired outcome both in terms of functionality and aesthetics.

You can find more design inspiration by exploring our wide range of panels today and make sure to stay informed about our latest releases by signing up to our mailing list below.

Words: Carley Eldridge